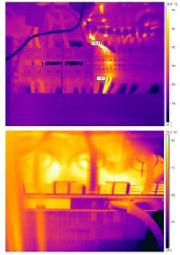

Spot your hot spots with Thermography

Thermography is a measurement method which provides a visual insight in the temperature of materials. Thermographic cameras produce pictures of invisible infrared radiation or heat radiation. Thanks to this technology it's possible to request thermal information from a device without making contact.

Infrared cameras has been used for inspection of eletrical installations, heating control by automatisation or development of processes, finding leaks, moisture and lack of isolation in buildings. Badly working bearings in engines, transmissions, conveyor etc.. can be detected rapidly.

An Infrared camera measures the infrared energy (heating radiation) without making contact, and convert it in to an electronic signal The camera convert this signal in to a thermal image and as a result of this it makes temperature calculations. The temperature that we can measure is up to 0.06°C precisely. We can measure temerature from -40°C up to +1500°C

Preventive maintenance

Infrared technology has itself developed up to one of the most valuable diagnosis methods in the field of preventive maintenance. By means of thermography, possible connections and electric circuits can be checked on bad assemblies or wear. loose screwing or bad connections are many causes which can create fire or bad functionality.

Thanks to thermography we can localise errors in the field of warmth loss, cold bridges, moistare, leak detection and much more...

See pdf (Dutch language) for more info!